News Releases

Rokmaster Reports Sensor-Based Sorting Gold Recovery of 99% at Revel Ridge

(Vancouver, September 5, 2023 – Rokmaster Resources Corp. (TSXV: RKR) (OTCQB: RKMSF) (FSE: 1RR1) (“Rokmaster” or “the Company”) is pleased to announce the receipt of very positive results from sorting test work on representative samples from the Revel Ridge Project (“Revel Ridge” or “the Project”) Main Deformation Zone (“MDZ”).

John Mirko, President and CEO of Rokmaster stated, “Rokmaster continues to improve recoveries and processing potential of all target metals. Achieving this excellent sorting result of recovering 98-99% of all the target metals to 50% of the screened sorter feed by being able to reject waste rock, sheds light on the ease of identifying the contacts between the mineralisation and waste types in this deposit and the potential to decrease the footprint of both the process plant and downstream tails facilities, while moving towards our ESG targets by being good stewards of energy consumption for processing.”

The test program was designed and supervised by Stacy Freudigmann, P.Eng., F.Aus.IMM. of Canenco Consulting Corp. (“Canenco”) and conducted at the Steinert US Inc. (“Steinert”) facility in Walton, KY, USA, with sample preparation and assaying undertaken at Base Metallurgical Laboratories Ltd. (“BaseMet”), out of Kamloops, BC.

The sorting objective was to remove the majority of the dilution waste rock types that would be present in mine output, in an effort to significantly upgrade the mineralization feed grade to the process plant. Two representative batches of bulk material from the MDZ, (Batch 1 and 2 of approximately 529kg and 739kg respectively), were prepped, compiled and submitted in consultation with the project mining engineers and geologists.

For this sorting program, a cascading test protocol utilizing the X-Ray Transmission (“XRT”) sensor was used. These steps would concentrate the densest fraction, and then the subsequent waste fraction from each pass would be tested with a lower threshold. This “cascade mode” allows for an understanding of the sorting behaviour under various sorting thresholds. Once the sorting algorithm was developed, the two batches of bulk material were fed into the sorter’s feed hopper and conveyor using a bobcat and after each separation stage, the product/waste streams were manually and visually examined to identify the extent, if any, of misplaced particles.

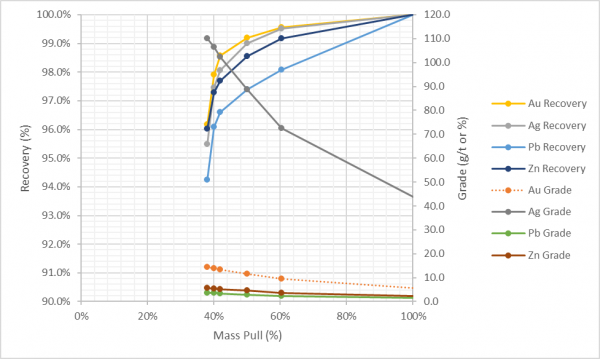

Figure1 – Average Sorting Test Results

| Average Batch 1&2 |

Calculated Data |

||||||||

|---|---|---|---|---|---|---|---|---|---|

|

Sorting Stage |

Cumulative Mass Pull to Product (%) |

Au Grade (g/t) |

Au Recovery (%) |

Ag Grade (g/t) |

Ag Recovery (%) |

Pb Grade (%) |

Pb Recovery (%) |

Zn Grade (%) |

Zn Recovery (%) |

|

Stage 1 |

38% |

14.5 |

96.2 |

110.0 |

95.5 |

3.6 |

94.3 |

5.6 |

96.0 |

|

Stage 2 |

40% |

14.0 |

97.9 |

106.4 |

97.4 |

3.5 |

96.1 |

5.4 |

97.3 |

|

Stage 3 |

42% |

13.5 |

98.6 |

102.4 |

98.1 |

3.4 |

96.6 |

5.2 |

97.7 |

|

Stage 4 |

50% |

11.6 |

99.2 |

88.8 |

99.0 |

2.9 |

97.4 |

4.5 |

98.6 |

|

Stage 5 |

60% |

9.5 |

99.6 |

72.4 |

99.5 |

2.4 |

98.1 |

3.7 |

99.2 |

|

Overall (Head) |

100% |

5.7 |

100.0 |

43.8 |

100.0 |

1.5 |

100.0 |

2.2 |

100.0 |

*Note: Some numbers may not add due to rounding.

Source: Canenco 2023

The Revel Ridge MDZ mineralisation exhibits excellent potential to be sorted using the XRT sorting sensor.

The results indicate that, based on the third separation threshold, over 98% of gold and silver can be concentrated in around approximately 42% of the mass, resulting in over 120% upgrade in the corresponding feed grades. At the fourth stage, where 50% of the feed was rejected, over 99% of the gold and silver was recovered to the product with approximately a 2x grade upgrade for all minerals of value.

The testing methodology undertaken provides a reliable tool to identify the best sorting conditions and thresholds and overall, these tests should satisfy a PEA-level of study. It should be noted that the current results were obtained in a controlled laboratory environment and may be optimistic compared to operational sorting scenarios. Operational results will vary with the changing feed conditions from the mine, variability in the deposit itself, actual dilution amounts and numerous other variables. In addition, the nature of cascading test work approach can be biased towards higher recoveries as particles get multiple chances to be sorted, although this doesn’t appear to be a major factor in the MDZ mineralization, it should be taken into consideration.

Further test work was recommended to support ongoing engineering studies.

• The concentrated material from these tests can be used for downstream metallurgical testing to estimate the potential effects on reagent consumption, lead, zinc, gold and silver recoveries, as well as any potential complications with the pre-concentration of impurities in the mineralisation.

• It was also recommended that additional confirmatory sorting tests (1-2 tonnes) to be

performed, with introduction of limited variability sample testing.

The technical information in this news release has been prepared in accordance with Canadian regulatory requirements has been reviewed and approved by Mr. Stacy Freudigmann, P.Eng. F.AusIMM., who is a Qualified Person as set out in National Instrument 43-101 and independent of Rokmaster.

For more information please contact Mr. John Mirko, President & CEO of Rokmaster Resources Corp., jmirko@rokmaster.com, Ph. 1-604-290-4647 or by website: www.rokmaster.com

For shareholder information please contact:

Mike Kordysz, mkordysz@rokmaster.com,Ph. +1 (604) 319-3171

On Behalf of the Board of Directors of

Rokmaster Resources Corp.

John Mirko,

President & Chief Executive Officer.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term in defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this press release.

About Rokmaster

Rokmaster’s flagship Revel Ridge Project is host to a high-grade gold and polymetallic orogenic sulphide deposit which has been the subject of a PEA Technical Report dated December 8, 2020, and an Updated Mineral Resource Estimate1 on the Revel Ridge Property with an effective date of June 6, 2023. The 2023 Mineral Resource Estimate remains open in all directions, and is the basis of the ongoing update to the PEA.

- Measured & Indicated (“M&I”): 1.53 million gold equivalent (“AuEq”) Measured & Indicated (“M&I”) ounces contained within 7.16 million tonnes with an average grade of 6.63 g/t AuEq.

- Inferred (Inf): 1.49 million AuEq ounces contained within 7.56 million tonnes at an average grade of 6.11 g/t AuEq.

Footnote 1. Stone et al. 2023. Technical Report and Updated Mineral Resource Estimate of the Revel Ridge Polymetallic Property. NI 43-101 Technical Report dated July 28, 2023.

CAUTIONARY NOTE REGARDING FORWARD LOOKING STATEMENTS: This news release may contain forward-looking information within the meaning of applicable securities laws (“forward-looking statements”). Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects,” “plans,” “anticipates,” “believes,” “intends,” “estimates,” ‘projects,” “potential” and similar expressions, or that events or conditions “will,” “would,” “may,” “could” or “should” occur. These forward-looking statements are subject to a variety of risks and uncertainties which could cause actual events or results to differ materially from those reflected in the forward-looking statements, including, without limitation: risks related to fluctuations in metal prices; uncertainties related to raising sufficient financing to fund the planned work in a timely manner and on acceptable terms; changes in planned work resulting from weather, logistical, technical or other factors; the possibility that results of work will not fulfill expectations and realize the perceived potential of the Company’s properties; risk of accidents, equipment breakdowns and labour disputes or other unanticipated difficulties or interruptions; the possibility of cost overruns or unanticipated expenses in the work program; the risk of environmental contamination or damage resulting from Rokmaster’s operations and other risks and uncertainties. Any forward-looking statement speaks only as of the date it is made and, except as may be required by applicable securities laws, the Company disclaims any intent or obligation to update any forward-looking statement, whether as a result of new information, future events or results or otherwise.